Protect Concrete Masonry

- By Tommy Bigham

- •

- 27 Aug, 2018

Keep your valuable masonry protected during construction

Architectural concrete masonry can easily be damaged by subs during construction. These occurrences can be prevented so that later repairs can be prevented. The many causes listed are fairly typical to any wall surface including dry wall and generally just as costly to repair.

A PDF of this blog can be found on the Resources page

CAUSES

• Mortar stuck on the faces of theblock

• Stains

• Large chips, scars on the face and corners of the block

• Concrete or grout splatter

• Pencil and Sharpie marks

• Drilled holes and cut holes by other trades

• Salt run

• Wet appearingmasonry

• Cleaning inconsistencies such as wand marks and incomplete rinsing

• Dirty feet or handmarks

• Ferrous Stains

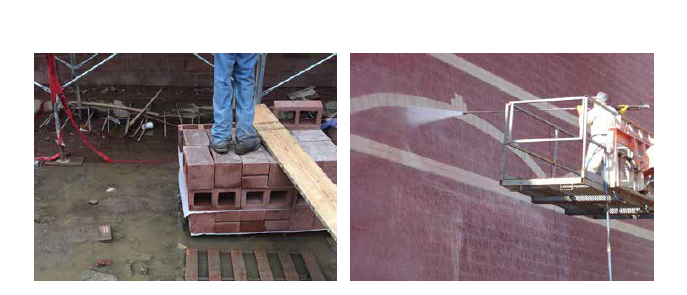

• Very careless handling of the masonry on thejob i.e. standing on them, scaffolding scars

• Other trades disregard for the finished wall by stacking materials against the finished surface running into the corners

SOLUTIONS

• In order to prevent damage to these finished walls, don’t allow feet to rest on the walls when leaning against them.

• Only under supervised circumstances allow tradesmen to mark the walls for any reason whether to layout junction boxes or measure marks.

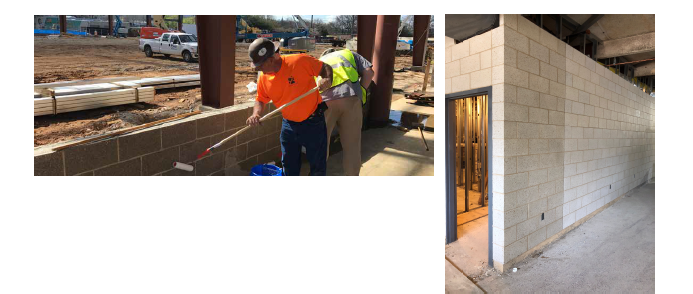

• Protect the walls from adjacent pouring of concrete floors or bond beams which will inevitably splash onto the walls

• Keep scaffolding and rolling equipment away from the walls and corners. Do not allow any equipment to lean against these walls.

• Protect the walls from work overhead such as roof installation and tar or asphalt installation

• Protect the corners and possibly the wainscoted area of the walls with plywood or similar material to prevent damage. Most of these damages occur in hallways.

• Follow the specifications and drawings religiously regarding the prevention of water intrusion into the building and its walls. All walls including interior walls are subject to the problems that are evidenced by salt run and efflorescence.

• Cover the tops of walls with plastic sheeting to prevent water intrusion into the cavity of the block throughout the job until the roof construction is totally complete.

• Solve water intrusion points immediately.

• The real answer to most of these problems is to simply communicate better the problems and their prevention to all on the jobsite. If all else fails then the walls must be protected with some form of barrie i.e. plywood or plastic which are also costly preventatives.

PROBLEM: Tape marks on the Filled and Polished walls

CAUSE: Paint trade masked off the walls when painting and used a strong adhesive tape.

SOLUTION: Clean with appropriate solutions

PREVENTION: The GC should supervise all trades consistent with the specifications.

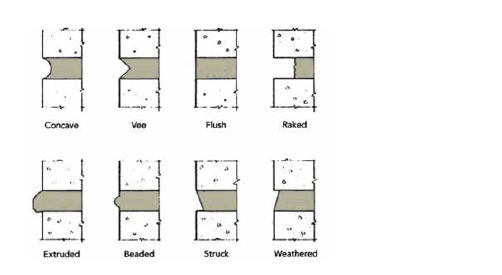

PROBLEM: Mortar or concrete on the face of the cmu

CAUSE: Probable splash from masons during installation

SOLUTION: Clean with approved masonry cleaners

PREVENTION: Protect the wall during installation, wipe down every day or more frequently.

PROBLEM: Scratched cmu faces from over zealous cleaning

CAUSE: Probable use of abrasive tools to remove mortar smears.

SOLUTION: jClean the face of the masonry with approved methods and chemicals - not abrasive tools

PREVENTION: Wipe down the faces of the cmu's every day or more frequently